The categories of small-pitch LEDs have increased, and they have begun to compete with DLP and LCD in the indoor display market. According to the data on the scale of the global LED display market, from 2018 to 2022, the performance advantages of small-pitch LED display products will be obvious, forming a trend of replacing traditional LCD and DLP technologies.

Industry distribution of small-pitch LED customers

In recent years, small-pitch LEDs have achieved rapid development, but due to cost and technical issues, they are currently mainly used in professional display fields. These industries are not sensitive to product prices, but require relatively high display quality, so they quickly occupy the market in the field of special displays.

The development of small-pitch LEDs from the dedicated display market to the commercial and civilian markets. After 2018, as the technology matures and costs decrease, small-pitch LEDs have exploded in commercial display markets such as conference rooms, education, shopping malls, and movie theaters. The demand for high-end small-pitch LEDs in overseas markets is accelerating. Seven of the world's top eight LED manufacturers are from China, and the top eight manufacturers account for 50.2% of the global market share. I believe that as the new crown epidemic stabilizes, overseas markets will soon pick up.

Comparison of small-pitch LED, Mini LED, and Micro LED

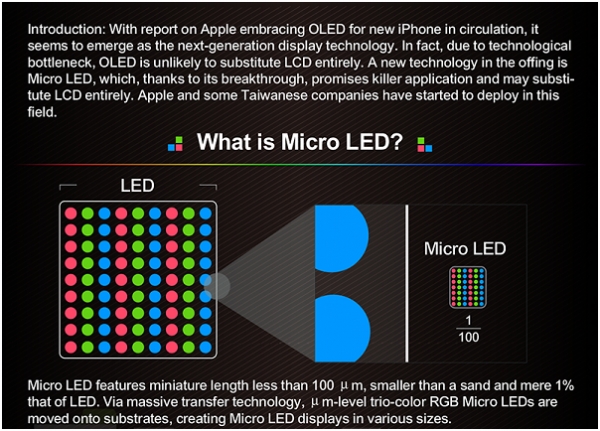

The above three display technologies are all based on tiny LED crystal particles as pixel luminous points, the difference lies in the distance between adjacent lamp beads and the chip size. Mini LED and Micro LED further reduce the lamp bead spacing and chip size on the basis of small-pitch LEDs, which are the mainstream trend and development direction of future display technology.

Due to the difference in chip size, various display technology application fields will be different, and a smaller pixel pitch means a closer viewing distance.

Analysis of Small Pitch LED Packaging Technology

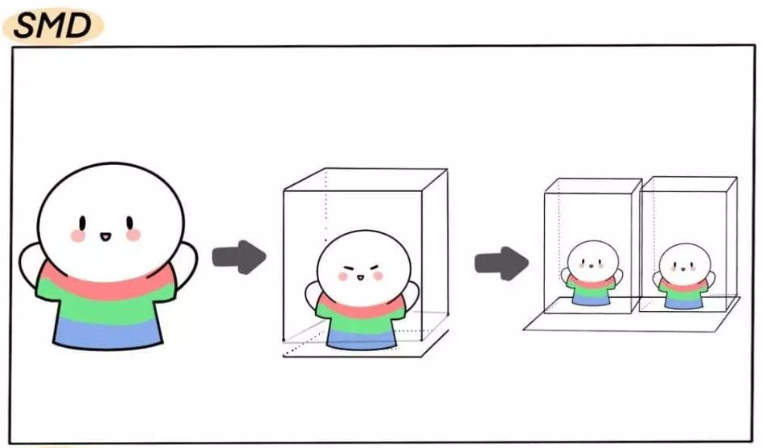

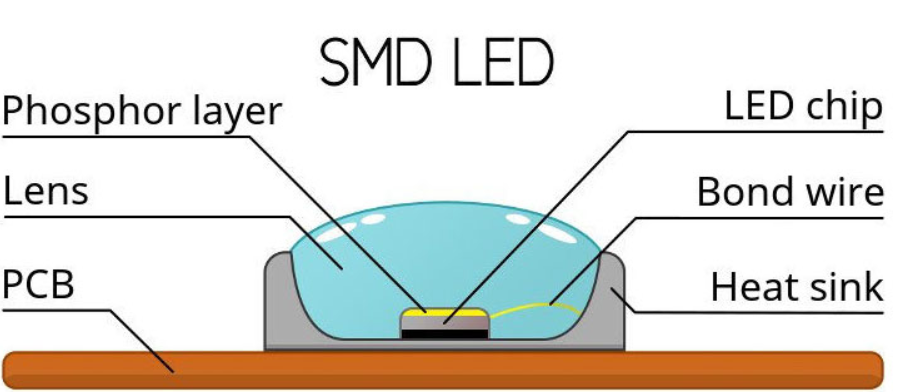

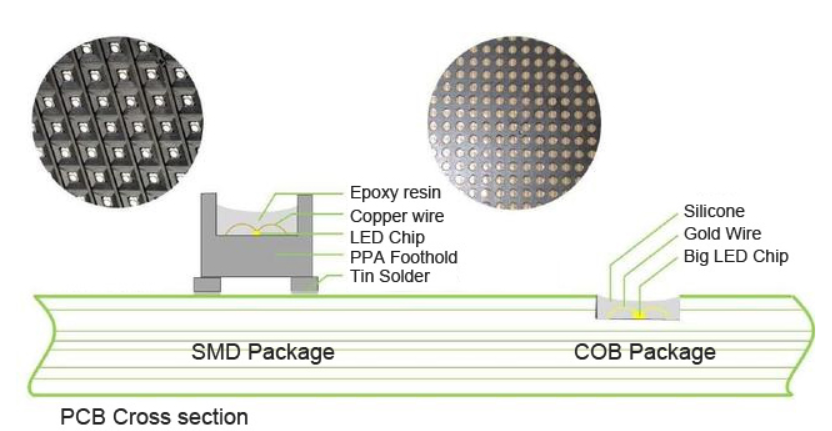

SMD is the abbreviation of surface mount device. The bare chip is fixed on the bracket, and the electrical connection is made between the positive and negative electrodes through the metal wire. The epoxy resin is used to protect the SMD LED lamp beads. The LED lamp is made by reflow soldering. After the beads are welded with the PCB to form the display unit module, the module is installed on the fixed box, and the power supply, control card and wire are added to form the finished LED display screen.

Compared with other packaging situations, the advantages of SMD packaged products outweigh the disadvantages, and are in line with the characteristics of domestic market demand (decision-making, procurement, and use). They are also the mainstream products in the industry and can quickly receive service responses.

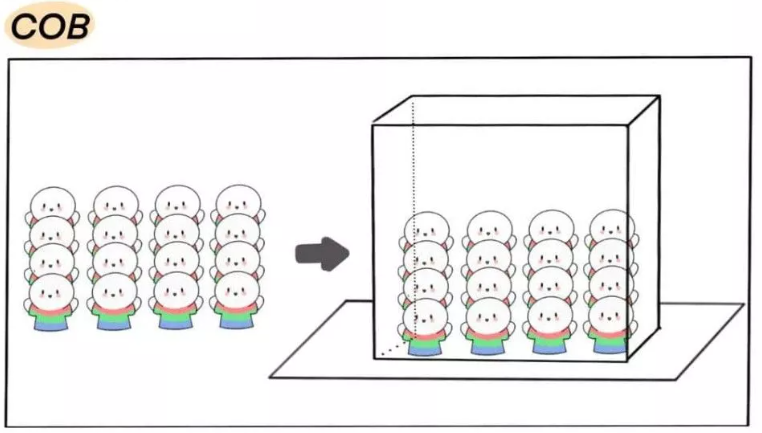

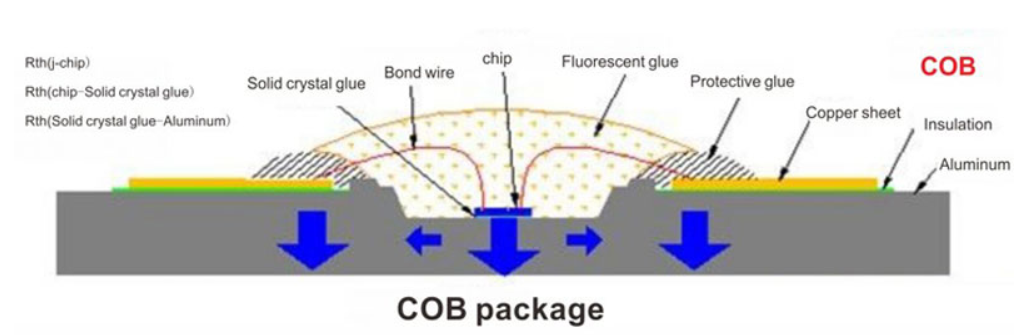

COB process is to directly adhere the LED chip to the PCB with conductive or non-conductive glue, and perform wire bonding to achieve electrical connection (positive mounting process) or using chip flip-chip technology (without metal wires) to make the positive and negative electrodes of the lamp bead directly connected to the PCB connection (flip-chip technology), and finally the display unit module is formed, and then the module is installed on the fixed box, with power supply, control card and wire, etc. to form the finished LED display screen. The advantage of COB technology is that it simplifies the production process, reduces the cost of the product, reduces the power consumption, so the display surface temperature is reduced, and the contrast is greatly improved. The disadvantage is that the reliability faces greater challenges, it is difficult to repair the lamp, and the brightness, color, and ink color are still difficult to do To consistency.

IMD integrates N groups of RGB lamp beads into a small unit to form a lamp bead. Main technical route: Common Yang 4 in 1, Common Yin 2 in 1, Common Yin 4 in 1, Common Yin 6 in 1, etc. Its advantage lies in the advantages of integrated packaging. The lamp bead size is larger, the surface mount is easier, and the smaller dot pitch can be achieved, which reduces the difficulty of maintenance. Its disadvantage is that the current industrial chain is not perfect, the price is higher, and the reliability is facing greater challenges. Maintenance is inconvenient, and the consistency of brightness, color, and ink color has not been resolved and needs to be further improved.

Micro LED is to transfer a huge amount of addressing from traditional LED arrays and miniaturization to the circuit substrate to form ultra-fine-pitch LEDs. The length of the millimeter-level LED is further reduced to the micron level to achieve ultra-high pixels and ultra-high resolution. In theory, it can be adapted to various screen sizes. At present, the key technology in the bottleneck of Micro LED is to break through the miniaturization process technology and mass transfer technology. Secondly, the thin film transfer technology can break through the size limit and complete the batch transfer, which is expected to reduce the cost.

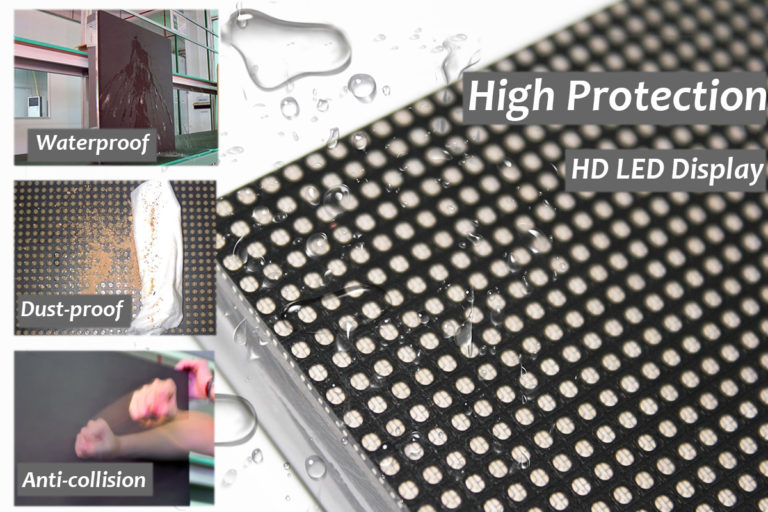

GOB is a technology for covering the entire surface of surface mount modules. It encapsulates a layer of transparent colloid on the surface of traditional SMD small-pitch modules to solve the problem of strong shape and protection. In essence, it is still a SMD small-pitch product. Its advantage is to reduce dead lights. It increases the anti-shock strength and surface protection of the lamp beads. Its disadvantages are that it is difficult to repair the lamp, the deformation of the module caused by the colloidal stress, reflection, local degumming, colloidal discoloration, and the difficult repair of the virtual welding.

Post time: Jun-16-2021